Valve Sizing

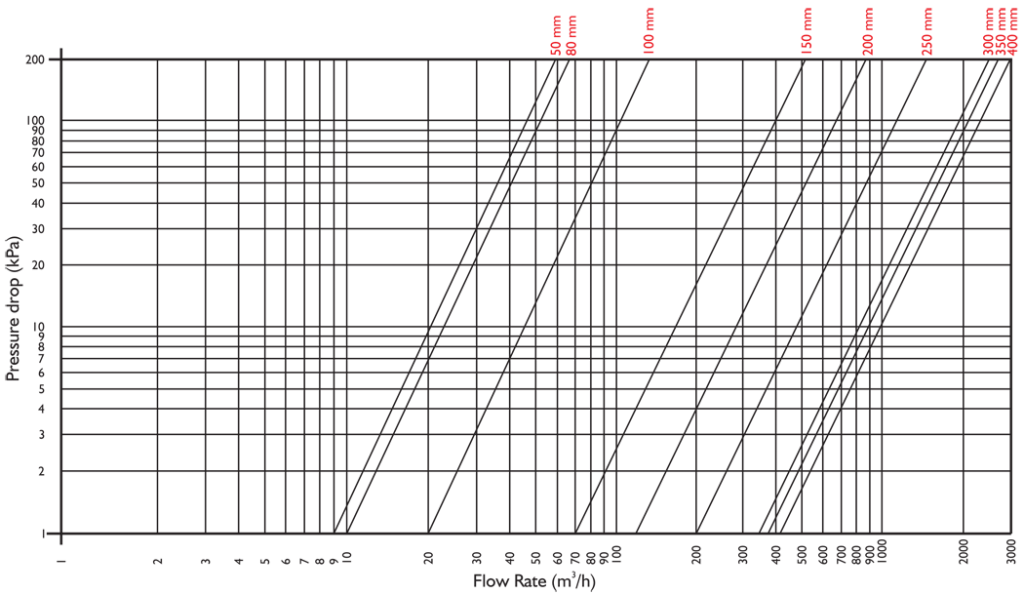

Pressure Drop Chart

| Valve Size | 50 mm | 80 mm | 100mm | 150 mm | 200 mm | 250 mm | 300 mm | 350 mm | 400 mm |

| Minimum Flow | 4.5 m³/h | 6 m³/h2 | 11.5 m³/h | 19 m³/h | 39 m³/h | 67 m³/h | 78 m³/h | 85 m³/h | 122 m³/h |

| Normal Flow | 44 m³/h | 69 m³/h | 129 m³/h | 310 m³/h | 508 m³/h | 905 m³/h | 1290 m³/h | 1501 m³/h | 1879 m³/h |

| Maximum Flow | 60 m³/h | 108 m³/h | 168 m³/h | 414 m³/h | 710 m³/h | 1120 m³/h | 1354 m³/h | 1940 m³/h | 2200 m³/h |

Normal flow @ 6m/s

Maximum flow @ 7.6m/s