Basic Control Valve Description

The FRASER valve is a Hydraulic Actuated Control Valve. The Globe pattern design provides reliable control and consists out of four major components namely; body, cover, seat and diaphragm-stem assembly. The compact design allows easy access for maintenance without removing the valve from the line.

The only moving part in the valve is the diaphragm-stem assembly. This assembly with a replaceable valve seal, seals drip tight on the seat. The stem assembly is standard guided in the valve seat and cover by renewable bushes. This allows smooth operation in any installed position. The quad seal retainer, quad seal washer and the valve seat is stainless steel to ensure that wear is reduced to the absolute minimum.

The unique “S”-shaped Globe pattern design has proved itself in various features including, stable control under various flow rates, low energy losses through fully open valve, less turbulence and high pressure reduction ratios.

The standard Fusion Bonded Epoxy coating (FBE) is applied internally and externally to the valve body, cover and wetted parts. Not only does this provides adequate protection against ambient corrosive conditions and environmental attack but also enhance flow through the valve.

Principle of operation

The FRASER Hydraulic Valve has three positions of operation namely: Open, Close and Modulating. The modulating function allows control upstream and downstream. The open/close function allows for on/off control and can be used in conjunction with modulation control. All functions are controlled with PILOT systems.

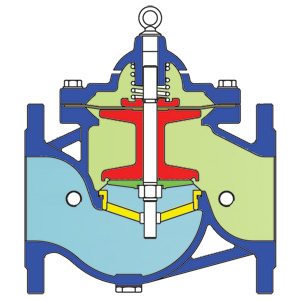

Closed Position

The line pressure is applied to the control chamber. The force in the control chamber push the diaphragm assemble onto the seat providing a drip tight seal.

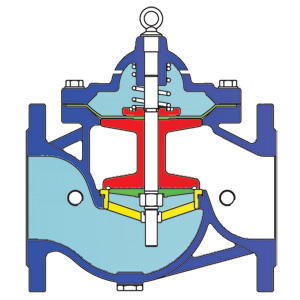

Open Position

The pressure in the control chamber is vented, allowing the line pressure to move the diaphragm assemble into the fully open position.

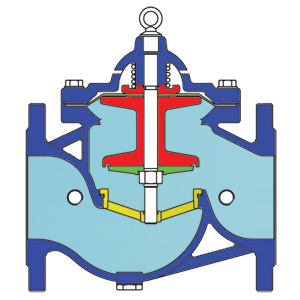

Modulating Position

The PILOT sense line pressure and will control chamber of the valve. This determines the intermediate position of the modulating valve under varying process conditions.